The main concept behind PEBs is the integration of engineering and manufacturing processes. Specialized engineers design buildings that meet specific requirements, considering factors such as load-bearing capacity, wind, snow and seismic loads, and other local regulations. During the design phase the engineering team ensures that the building is structurally sound and optimized for its intended use.

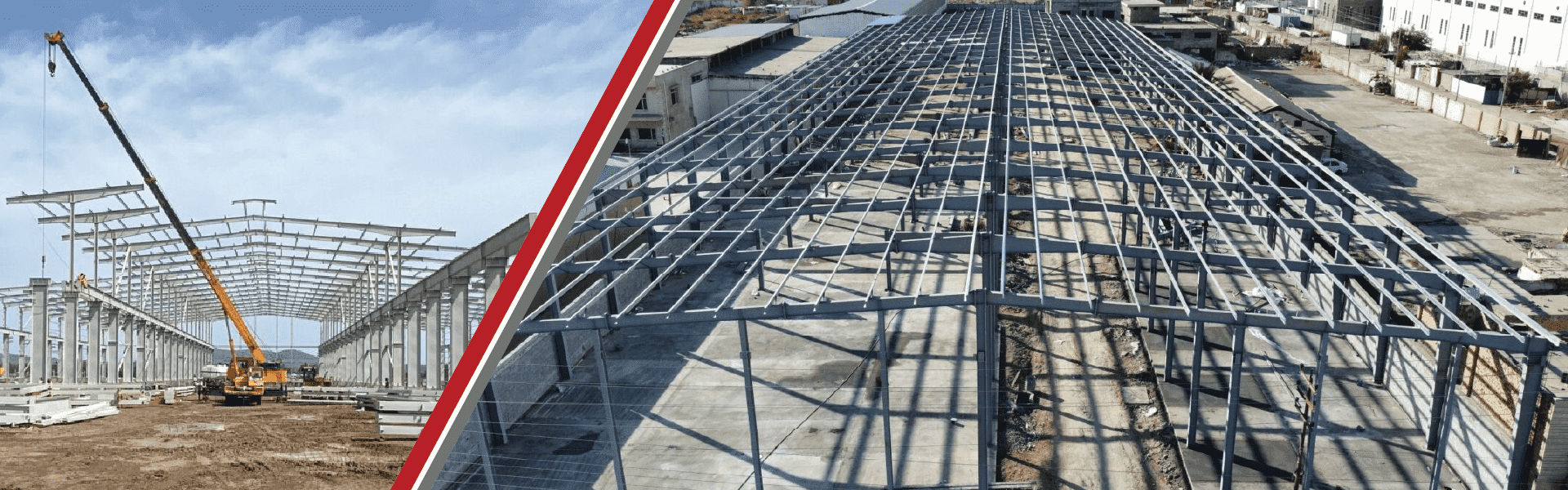

Once the design is finalized, the manufacturing process begins. Steel components, including columns, rafters, purlins, girts, roof and wall panels, are fabricated in a controlled factory environment. The use of standardized components allows for precise manufacturing, ensuring consistency and accuracy throughout the building process.

One of the primary advantages of PEBs is their speed of production since the components are fabricated using standardized raw material which is readily available in the manufacturer’s raw material yard. The materials are efficiently transported to the construction site and assembled easily and quickly. This significantly reduces construction time and in turn total project time compared to traditional methods, enabling projects to be completed in a fraction of the time.

PEBs offer exceptional versatility. The design can be customized to meet specific requirements, allowing for various building sizes, configurations and architectural styles. The flexible nature of steel as a building material enables wide-span designs, creating large, open interior spaces without the need for intrusive support columns.

Pre-engineered steel buildings are also renowned for their durability and strength ensuring a long lifespan with minimal maintenance. Additionally, steel buildings can withstand extreme weather conditions, including high winds, heavy snow loads and seismic activity, providing a safe and secure environment.

We are dedicated to providing versatile solutions, with applications extending to, but not limited to: